The Facts About Plant Conveyors And Systems Uncovered

Table of ContentsSome Known Factual Statements About Plant Conveyors And Systems About Plant Conveyors And SystemsSee This Report on Plant Conveyors And SystemsA Biased View of Plant Conveyors And SystemsThe Greatest Guide To Plant Conveyors And Systems

Published On: November 11, 2019 With so numerous different alternatives, it can be hard to understand what type of conveyor systems to use in your storehouse automation. Right here are 20 usual kinds of conveyors. If you need aid picking systems for your storage facility, call DCS. This is most likely what you imagine when you consider a conveyor.It is developed at a small decrease so components slide downward by themselves. This resembles a gravity roller conveyor except a chain or belt is made use of to make the rollers activate their very own, so they do not need to be improved a decrease. In some cases they can even rise.

Container conveyor systems are utilized to relocate material vertically, by scooping it with a collection of buckets connected to a belt, chain, or wire. The conveyor moves the containers up, scooping up the product, and also carrying it to the top prior to unloading it out. explains this sort of conveyor system: "Ball Transfer tables or conveyors make use of a collection of installed sphere casters to permit unpowered, multi-directional transportation of the item." Basically, think of rows of metal balls on a table that can transform and revolve in any instructions.

The 8-Second Trick For Plant Conveyors And Systems

Instead of having rollers or a belt, they have relocating chains to carry products. There is an entire family members of conveyors that lug their tons under them instead of on top of them.

Sometimes, as with the Power-and-Free Conveyor, they have two tracksone mechanized as well as one not motorized. Turn a trolley conveyor upside down, affix it to the floor instead of the ceiling, and also you have actually got an inverted monorail. This conveyor vibrates slightly to relocate bulk product along it.

What Does Plant Conveyors And Systems Mean?

There are likewise other associated devices that use a chain to drag items such as a tubular drag conveyor. These conveyors make use of a vacuum cleaner or air pressure to relocate material.

They raise them approximately a various degree of the storehouse. They are not huge enough to lift people, nonetheless. These are similar to a roller conveyor except with little, private wheels rather than long, round rollers. Walking Beam of light conveyors move product incrementally along the conveyor making use of moving and fixed supports.

If why not check here you require help selecting a conveyor system, allow us know. We have over 35 years of experience working with jobs big (approximately $30 million) as well as small.

The Facts About Plant Conveyors And Systems Uncovered

Introduction The full overview to conveyor systems on the internet. Conveyor System Needs Types of Conveyor Systems Exactly How Does a Conveyor System Work?

Load Capability: Once the system has actually been laid out as well as given a pattern, it has actually to be identified what will be the quantity of materials it can bring - Plant Conveyors and Systems. Overwhelming a system can harm it or create it to drop in the midst of its procedure. Aspects that see influence the lots ability are overall size as well as bed size along with the drive system.

5 Simple Techniques For Plant Conveyors And Systems

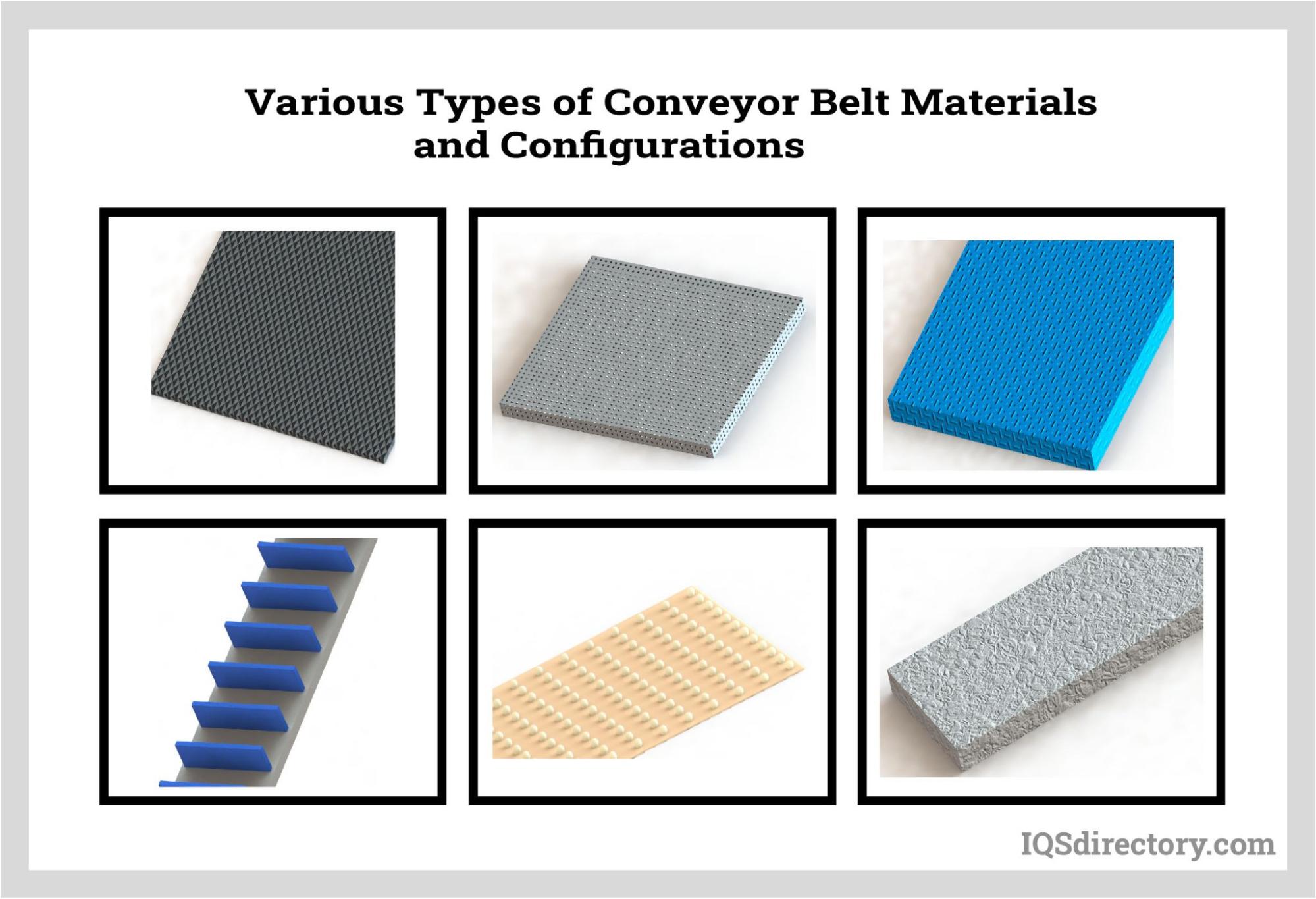

Movement of powdered, granular, and chip kind products can have dirt accumulate, which is thought about in system layout and also might necessitate some type of purification. As with various other communicating systems, a cautious assessment of the attributes of the material is required. Configuration: Conveying systems come in a wide range of shapes, designs, sizes, as well as kinds.

Because each system is designed to fit an unique application, it would be impossible to cover every one of the different configurations. What is essential to understand is that there are very couple of limitations on including a conveying system, no matter the application. Drive System: The drive of an automated communicating system is the power that moves products.